Swift cuts

tailored to your vision

Hours

Monday – Friday

8 AM – 4 PM

Saturday – Sunday

Closed

Phone

Address

3309 SW 11th Ave

Fort Lauderdale, FL 33315

Services

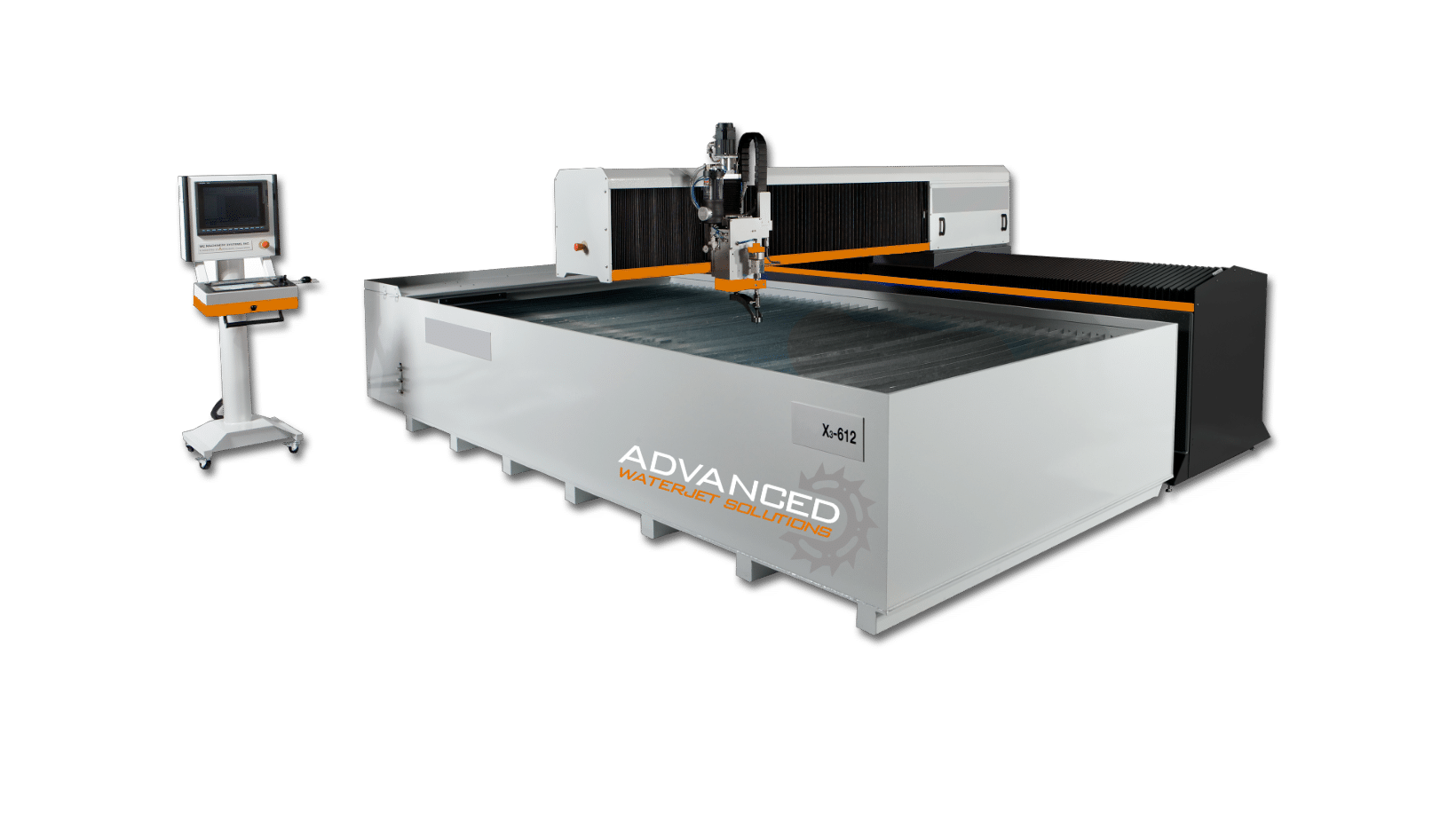

Waterjet Cutting

Unparalleled precision and versatility, enabling the creation of intricate and complex designs with minimal material waste.

Laser Engraving

Engrave your parts with a stock # or take your business all the way with engraved tumblers, business cards, etc.

Schedule Pickup

Rush jobs are at a 95% acceptance rate with Advanced Waterjet Solutions.

We Cut

With multiple waterjet machines, we typically cut your designs same-day!

Same Day Pickup

In little to no time, your parts can be ready for pickup same-day!

DESIGN

Custom work is our strong suit. Fully trained cad engineers help convert your project necessities into reality. From hand drawn sketches to complicated dwg files, we read and convert any format. Our nesting software assures the most efficient cuts with minimal waste.

QUALITY

All of our cuts come from software-controlled, robotic motion systems that can ensure tight tolerances. With multiple cut settings, the need for secondary finishing methods is eliminated. The extremely thin water stream ensures minimal material loss.

custom work

With engineers adept at recreating hand-made parts, we can turn around custom projects reasonably fast with low costs.

cost-efficiency

With a waterjet cut, you’re able to skip a few steps and optimize production speed. With cuts extremely precise, minimal material is wasted and products are ready for manufacturing without the need to tamper.

instant quote

Now incorporating our online quoting tool, we can receive your order files and generate a quote within minutes! Get started and receive a same-day quote.

DESIGN

Custom work is our strong suit. Fully trained cad engineers help convert your project necessities into reality. From hand drawn sketches to complicated dwg files, we read and convert any format. Our nesting software assures the most efficient cuts with minimal waste.

QUALITY

All of our cuts come from software-controlled, robotic motion systems that can ensure tight tolerances. With multiple cut settings, the need for secondary finishing methods is eliminated. The extremely thin water stream ensures minimal material loss.

custom work

With engineers adept at recreating hand-made parts, we can turn around custom projects reasonably fast with low costs.

cost-efficiency

With a waterjet cut, you’re able to skip a few steps and optimize production speed. With cuts extremely precise, minimal material is wasted and products are ready for manufacturing without the need to tamper.

instant quote

Now incorporating our online quoting tool, we can receive your order files and generate a quote within minutes! Get started and receive a same-day quote.

About Advanced Waterjet Solutions

At Advanced Waterjet Solutions, we don’t just cut metal; we sculpt visions into reality, setting a new standard for precision in the world of custom metal fabrication. Armed with cutting-edge waterjet technology, we specialize in delivering unmatched metal-cutting solutions that redefine the standards of accuracy and efficiency. Our commitment to excellence is evident in every project, where we seamlessly blend advanced machinery with a team of skilled experts. With a focus on versatility, sustainability, and client satisfaction, we stand as industry leaders, offering a comprehensive suite of services tailored to meet the unique needs of our diverse clientele.

About Advanced Waterjet Solutions

At Advanced Waterjet Solutions, we don’t just cut metal; we sculpt visions into reality, setting a new standard for precision in the world of custom metal fabrication. Armed with cutting-edge waterjet technology, we specialize in delivering unmatched metal-cutting solutions that redefine the standards of accuracy and efficiency. Our commitment to excellence is evident in every project, where we seamlessly blend advanced machinery with a team of skilled experts. With a focus on versatility, sustainability, and client satisfaction, we stand as industry leaders, offering a comprehensive suite of services tailored to meet the unique needs of our diverse clientele.

Find the right material to fulfill the job

Find the right material to fulfill the job

What makes

The ultimate solution

Precision + Accuracy

Waterjets can cut with high precision, allowing for tight tolerances and intricate designs. The most ideal application for projects where precision is critical.

Material Variety

With support from multiple vendors, we have a selection of 300+ distinct sheets in various lengths, materials, and thicknesses.

Minimal Material Waste

When customers supply material, we’re always returning more than they expected. Waterjet cutting minimizes material wastage because of our nozzle’s kerf (cutting width) allowing an extremely tight tolerance. This ability to cut precisely allows us to nest your parts close to one another without intervention. This, in turn, optimizes material usage.

Eco Friendly

Waterjet cutting is an eco-friendly method as it uses water and abrasive materials for cutting, without producing harmful fumes or byproducts. It is a clean and sustainable process.

No Mechanical Stresses

Unlike some cutting methods that introduce mechanical stresses, waterjets are non-contact cutting tools. This prevents distortion or warping of the material, maintaining its structural integrity.

No HAZ – Heat-Affected Zone

Waterjet cutting is a cold-cutting process, meaning it doesn’t generate heat during cutting. This eliminates the risk of altering the material’s properties due to heat, making it suitable for heat-sensitive materials.

Versatility

Waterjets can cut a variety of materials, including metals (such as steel, aluminum, and titanium), plastics, ceramics, glass, and composites. This versatility makes them suitable for diverse industries.

Complex Geometries

Waterjets excel at cutting complex shapes, bevels, and 3D contours. This capability is valuable for producing intricate and customized parts.

rush orders, same day

Why not cut ahead? With multiple waterjet tables, we can usually process your orders on the same day!

What makes

The ultimate solution

Precision + Accuracy

Waterjets can cut with high precision, allowing for tight tolerances and intricate designs. The most ideal application for projects where precision is critical.

Material Variety

With support from multiple vendors, we have a selection of 300+ distinct sheets in various lengths, materials, and thicknesses.

Minimal Material Waste

When customers supply material, we’re always returning more than they expected. Waterjet cutting minimizes material wastage because of our nozzle’s kerf (cutting width) allowing an extremely tight tolerance. This ability to cut precisely allows us to nest your parts close to one another without intervention. This, in turn, optimizes material usage.

Eco Friendly

Waterjet cutting is an eco-friendly method as it uses water and abrasive materials for cutting, without producing harmful fumes or byproducts. It is a clean and sustainable process.

No Mechanical Stresses

Unlike some cutting methods that introduce mechanical stresses, waterjets are non-contact cutting tools. This prevents distortion or warping of the material, maintaining its structural integrity.

No HAZ – Heat-Affected Zone

Waterjet cutting is a cold-cutting process, meaning it doesn’t generate heat during cutting. This eliminates the risk of altering the material’s properties due to heat, making it suitable for heat-sensitive materials.

Versatility

Waterjets can cut a variety of materials, including metals (such as steel, aluminum, and titanium), plastics, ceramics, glass, and composites. This versatility makes them suitable for diverse industries.

Complex Geometries

Waterjets excel at cutting complex shapes, bevels, and 3D contours. This capability is valuable for producing intricate and customized parts.

rush orders, same day

Why not cut ahead? With multiple waterjet tables, we can usually process your orders on the same day!

a proud partner-company with

Hours

Monday: 8 AM – 4 PM

Tuesday: 8 AM – 4 PM

Wednesday: 8 AM – 4 PM

Thursday: 8 AM – 4 PM

Friday: 8 AM – 4 PM

Saturday: Closed

Sunday: Closed

Hours

Monday: 8 AM – 4 PM

Tuesday: 8 AM – 4 PM

Wednesday: 8 AM – 4 PM

Thursday: 8 AM – 4 PM

Friday: 8 AM – 4 PM

Saturday: Closed

Sunday: Closed

Address

3309 SW 11th Ave, Fort Lauderdale, FL 33315

Follow

Other Links

Privacy Policy

Terms & Conditions